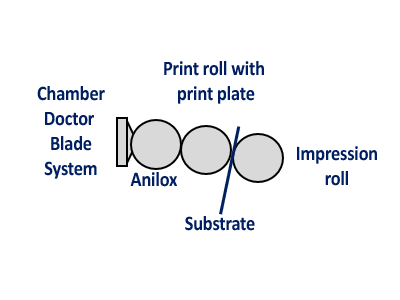

What is flexographic printing?Flexo is the industry term for flexographic printing and the basic principle is illustrated on the above photo. Today flexographic printing is a high definition printing technology. The technology behind flexographic printing combines high speed rotation with a raised positive mirrored master of the required print image in a rubber or polymer material – produced with either an analog or a digital platemaking technology. The image areas are raised above the non-image areas on the rubber or polymer plate. The printing plate is then mounted on a sleeve or print cylinder with a plate mounting tape.

In order to control the amount of ink on the printing plate, a doctor blade is used to remove excess ink from the anilox roll before inking the printing plate. The substrate is then placed in between the printing plate and an impression cylinder and the print image is transferred. Each print unit in a flexographic printing press normally includes: - Anilox roll: Cylinder engraved with small cells in a specific angle and with the right volume to deliver the required print image for a print job - Chamber doctor blade system: Contains a measured amount of ink transferred to the cells of the anilox roll - Plate cylinder: Printing plate with a raised positive mirrored master of the required image - Impression cylinder: Sleeve supporting the substrate as the printing plate is pressed against it - Ink supply system: Transfers the ink to and from the chamber doctor blade system and can be used to control flow, temperature, viscosity and pH levels. Water-based inks, solvent-based inks and UV-based inks are all available for use with the flexo printing technology. Contact us for more information sales@tresu.com. | |||