Looking to upgrade or retrofit your production line?

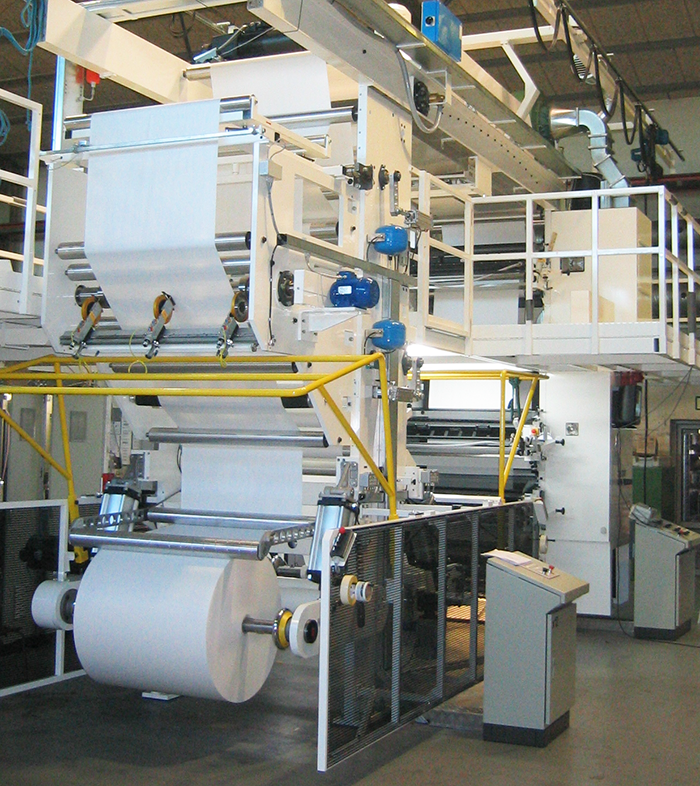

Flexo Retrofits or Upgrades for Coating, Printing and Gluing

If you think, that the current business climate is not mature for any large capital investments, then there are many other efficient ways to upgrade or retrofit your production line – and achieve a fast return on the upgrade:

We can increase your capacity from existing installations or optimize the efficiency - and we have several different ways of doing this: Either with TRESU Machine Upgrades or with TRESU Retrofit Solutions in existing production lines with additional flexo units for either Coating, Gluing or Printing

TRESU offers a wide selection of Flexo retrofit solutions for Printing, Coating and Gluing Solutions onto almost every type of converting machine on the market. As a global provider of machines and equipment, we offer our expertise and solutions to integrate flexographic technology to apply various coatings, inks and glue to practically any type of surface.

Genuine Spare Parts are available from our Global Webshop or Webshop US / Americas Explore our customer service and technical support program: Customer Care Download: Flexo Unit brochure or watch here: TRESU Flexo Solution [MP4]

|

Applications for flexo units and machines | |

|

Standard Flexo solutions

NWG1 For narrow web applications Width 185-1.100 mm Speed 1-200 m/min Repeat 140-610 mm Gear wheel driven | MWG1 For mid web applications Width 670-1.700 mm Speed 100-300 m/min Repeat 600-1000 mm Gear wheel driven | HS1 For high performance applications Width 185-1.700 mm Speed 300-1.000 m/min Repeat 340-660/600-1000/800-1560mm Servo driven |

NWS1 For narrow web applications Width 185-670 mm Speed 100-400 m/min Repeat 500-760mm Servo driven | WWG1 For wide web applications Width 1.700-3.500 mm Speed 1-400 m/min Repeat 800-2000mm Gear wheel driven | HS2 For high performance applications Width 1.700-3.500 mm Speed 300-1.000 m/min Repeat 800-2000mm Servo driven |

Width Speed | 100 m/min | 200 m/min | 300 m/min | 400 m/min | 600 m/min | 800 m/min | 1000 m/min |

150 - 670 mm | NWG | NWG | NWS | NWS | HS1 | HS1 | HS1 |

670 - 1100 mm | NWG | MWG | MWG | HS1 | HS1 | HS1 | HS1 |

1100 - 1700 mm | MWG | MWG | MWG | HS1 | HS1 | HS1 | HS1 |

1700 - 2500 mm | WWG | WWG | WWG | WWG | HS2 | HS2 | HS2 |

2500 - 3500 mm | WWG | WWG | HS2 | HS2 | HS2 | HS2 | HS2 |

Lackierwerk Lackier Leim Leimwerk Druck,