TRESU Inline CI Flexo Technology:

Boost your brand and your business.

A single pass converting line with integrated TRESU inline CI flexo printing technology optimizes the ability to meet brand owners' demand for branded goods, while having the flexibility to competitively offer shorter production runs and shorter lead-times - with costs firmly controlled.

For applications with 80-800 mm web width and production speeds up to 600 m/min, TRESU inline CI flexo printing machines can reduce brand owners' time to market and offer an opportunity for frequent design changes in response to seasonal trends or fashion demands.

Inline flexo printing also reduces stock complexity, logistics and dependence on pre-printed materials.

With compact housings and build-in measures TRESU inline CI flexo printing machines are ideal for printing, where space is limited, but quality requirements are high.

Click to view: PRINTER FOR SANITARY NAPKINS | Click to view: PRINTER FOR POUCHES |

PROVEN DESIGN FEATURES OF TRESU CI FLEXO PRINTING TECHNOLOGY:

Customized solutions with 1,2,3 or 4 colors (upgradable)

Up to 1,960 ft/min (600 m/min) and web width from 3.1" to 31.4" (80 - 800 mm)

Precise register with minimum waste

Substrates: Non-woven, films or laminate

State of the art drying technology

Temperature control and dryers between each color unit

Air cushioned sleeve change technology: Job change in less than 5 minutes

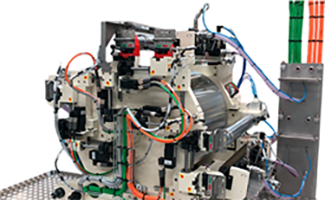

Pressure Control Technology:

Foam free transfer of ink or coating with TRESU's genuine chamber doctor blade systemsHighest standards of safety

Operator friendly HMI design with fast recipe recall

Automation of ink supply, viscosity and cleaning

Click to download the leaflet Boost Your Brand

NONWOVEN: TRESU INLINE CI FLEXO TECHNOLOGY FOR PRINTING OF SANITARY NAPKINS. | |||

|

| ||

POUCH PRINTING: TRESU INLINE CI FLEXO TECHNOLOGY FOR PRINTING OF POUCHES. | ||

|

| |

TRESU CI FLEXO TECHNOLOGY HIGHLIGHTS:

Fast drying: |

Fast job change: |

No foam, no contamination: | ||||

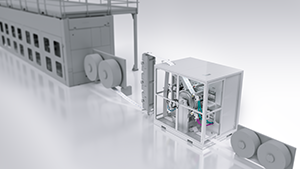

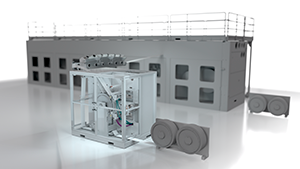

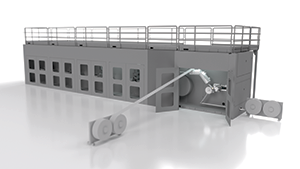

FOUR WAYS OF INTEGRATING INLINE CI FLEXO TECHNOLOGY:

TRESU has developed four ways of integrating the printing process with existing converting machines, based on many years’ retrofitting experience in the manufacturing sector.

Switching to CI flexo technology from TRESU you increase your uptime and flexibility and though installations like drain are necessary, the advantages are substantial in the long run.

With 40 years of experience working with leading brands from all over the world, TRESU can recommend how to integrate CI flexo technology most efficiently and train and educate any staff to be able to operate the inline CI flexo printing machine from TRESU.

|

Direct inline print unit |

Parallel inline print unit |

90° inline print unit |

Integrated inline print unit |

Our CI flexo design can be integrated in four different ways - feel free to reach out and let us discuss how to find the best way for you:

Contact information:

FREDERIK TEISNER

SALES & TECHNICAL MANAGER

TRESU A/S

EMAIL: FTE@TRESU.COM

sales@tresu.com

What is CI press - what is a central impression CI flexo printing machine?

Central impression - CI flexo printing is a print press where the decks are arranged around a single, large diameter impression cylinder as opposite to stack flexo presses with decks above one another and as opposite to inline flexo where the print units are oriented horizontally in a line.