TRESU iCoat II - Digital and modular for short-run print jobs

TRESU iCoat II is a great leap up to a new level of coating for sheet-fed applications in short-run digital print jobs, requiring fast job changes and production speeds up to 6,000 sheets/hour and paper sizes up to B2.

On top of this, the stand-alone TRESU iCoat II is designed on a modular platform, on which you can combine a range of different modules to configure the machine exactly to your needs.

You buy what you need - no more, no less.

Efficient design features for short-run digital print jobs:

| DOWNLOAD | WATCH |

The modular TRESU iCoat II targets a broad span of configurations - right from a flexible combi-coater for general folding carton applications - to an efficient twin coater configuration with more advanced single pass finishing operations for high-end carton.

For pharmaceutical packaging applications an inspection conveyor module can be added delivering traceability and inspection of individually marked units.

Versatile combi-coater for general folding carton applications - GFC To produce GFC often requires many different types of coating and the solutions is a combi-configuration with separate circuits for fast response to changes between WB and UV coating jobs: | |||

| • Dual varnish system with separate WB and UV circuits ensures secure fast changes between UV and WB jobs • Flood and spot coating • Efficient hot air drying • WB/UV anilox and plate sleeves included • PLC for recipe management |  | |

Single WB varnish coater for pharma applications. Traceability, inspection and individual marking of each individual unit are key design parameters in pharmaceutical packaging. | |||

| • Inspection conveyor module • Single WB varnish configuration • Coating knockouts (for bar codes, ID and QR codes) as well as glue flaps • Ejection tray for rejected sheets • Efficient hot air drying • PLC for recipe management |  | |

Feel free to contact us for further information on the modules for your coating application: sales@tresu.com

|

TRESU iCoat II TECHNICAL HIGHLIGHTS:

TRESU iCoat II is engineered and designed on a modular platform tuned to your needs. This allows you to choose the features you need now - and add optional features when you need them.

|

Fastest job change in the industry: |

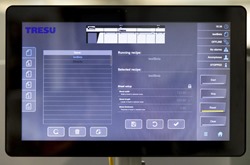

Fast set-up and easy job changes with HMI recipe storage: |

Proofing on the run – means full test control, visual inspection and samples with no downtime. | ||

Automatic cleaning at the push of a button: Separate WB and UV systems means faster cleaning, less down-time and less handling. |

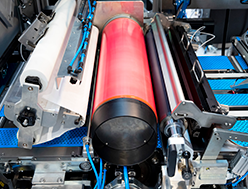

Proven TRESU flexo technology delivers printing efficiency designed to last. |

Genuine TRESU chamber doctor blade system designed for fast handling and great performance. |

Contact information:

FREDERIK TEISNER

SALES AND TECHNICAL MANAGER

TRESU A/S

EMAIL: FTE@TRESU.COM